Superior Product

Design Starts with

Superior Fiber

Selection

Clinically Clean Products

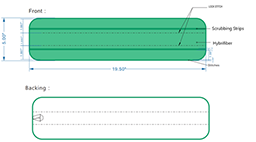

Flat Mops

Cloths

Food Service Cloths

The Challenge is that you must be capable of picking up microbial

soil loads while releasing your cleaning chemistry onto the

surface to properly disinfect.

Fiber characteristics are critical for proper cleaning. The challenge is that you need to be capable of removing microbial soil loads while also releasing your cleaning chemistry onto the surface to properly disinfect. Essentially you need to pickup soil loads while simultaneously releasing your chemicals onto the surface. Some cleaning products are highly effective at releasing while others are highly effective at picking up and holding onto dirt and microbes. Most products on the market today focus on removal but are not properly releasing active ingredients therefore quat binding occurs. When quat binding occurs, you are not getting the proper cleaning ingredients parts per million onto the surface. When your parts per million are inaccurate, the chemistry doesn’t achieve the proper dwell to kill bacteria and viruses.

In short it is like you’re cleaning you surfaces with water. A cleaning professional

should envision themselves a painter coating floors and surfaces. They need

proper saturation and must coat the surface adequately to stay wet for “X”

minutes while the cleaning chemicals do their job. Most professionals are

focused on what they can visually see which is soil load removal, but its more

important to focus on what you cannot see; killing surface pathogens. Professionals who focus on surface coating inherently also achieve proper soil removal. Another common problem we see is facilities using single use disposable mops and towels to clean surfaces.

These products are designed to be inexpensive so that a single use disposable systems can be affordable. Often times a cleaning professional must use more mops, towels, or wipers because the low pile of the product is not capable of high soil retention. The lack of grams per square meter (thickness) also means the products cannot be a carrying vessel of cleaning solution to cover surfaces adequately to get proper dwell times. Single use disposables usually get 1/2 to 1/3 of the square foot coverage per towel or mop of the equivalent Clinically Clean product.

Clinically Clean products are made exclusively with Hybrifibers. Hybrifiber products are specially engineered to achieve superior disinfection. They are the proper GSM (thickness) to achieve proper soil removal, while not being too high a GSM that you begin to face issues with quat binding or chemical release onto the surface being disinfected. Hybrifiber is made

of durable synthetic fibers. Fiber durability is a key component

to proper cleaning so that the product can be properly cleaned and

removal of bioburden can be achieved. Some products such as microfiber are more delicate fibers. When a facility has to use a more delicate wash process

it becomes much harder to remove bioburden and laundry residues. Every new facility that launches Clinically Clean is also provided complementary Chemistry Compatibility Testing. This is our way of ensuring our products do not interfere with your cleaning chemistry

This is core to our mission which is protecting employees, patients & visitors from threats invisible To the naked eye.